Robot Safety

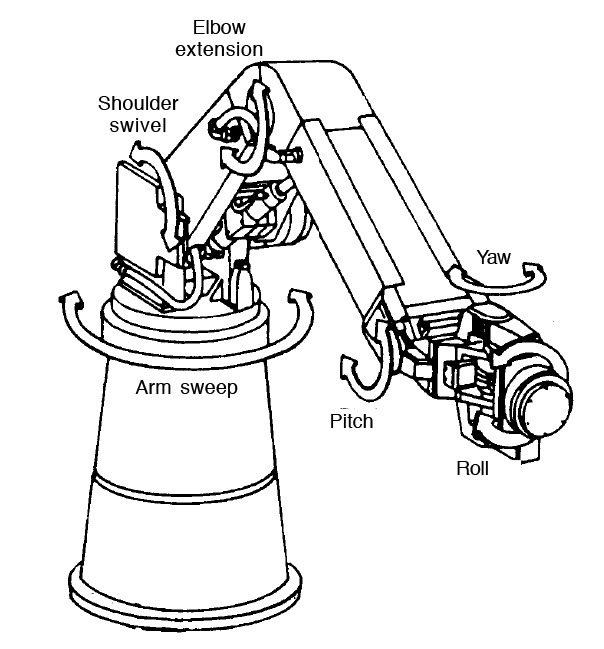

A robot is a mechanism, guided by automatic controls, which performs repetitive work such as moving portable tooling into position, moving workpieces from one location to another, and/or assembling one or more workpieces. However, the robot’s automatic movement and flexibility present significant hazards to its human operators, maintenance, and programming personnel.

To ensure the safety of operations and support personnel, a systematic program for Robot Safety should be developed and implemented.

Such a Robot Safety Program should include all phases of robot operation. Specifically:

Process planning phase

- Determine need for using a robot

- Select appropriate robot for task requirements

- Obtain robot manufacturer’s specifications

- Review and evaluate robot design safety features–mechanical, electrical, software

- Review and evaluate robot testing and evaluation–initial start-up, emergency handling, software, sensory devices, static performance, dynamic performance

- Design a safe work process and work organization – operator location, prevention of human errors, malfunction procedures, gripper selection, sensing devices, tool overload, overall robot safety responsibility and accountability

- Provide training – for operators, supervisors, maintenance and programming personnel, and engineers; develop disciplinary action program for safety rule violators; refresher training program once initial training has been completed

Installation phase

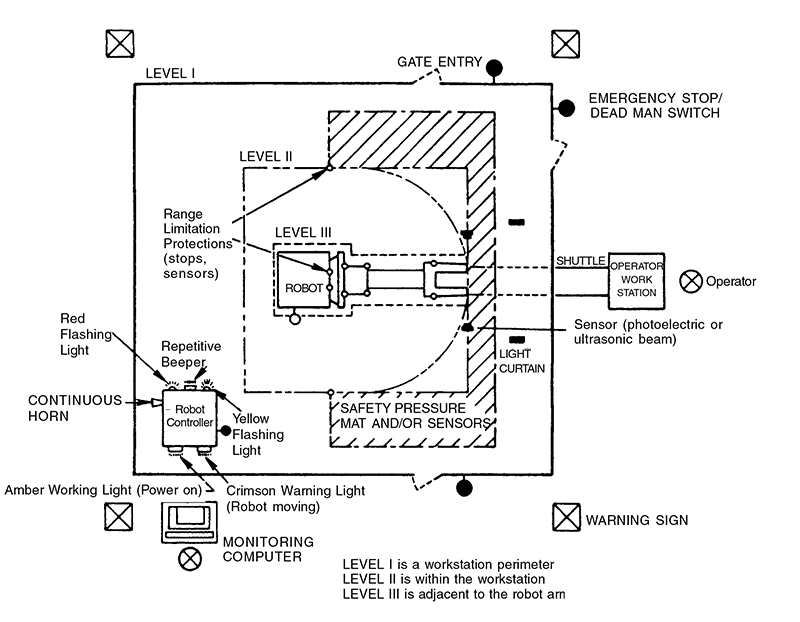

- Safe workplace design – physical layout, electrical consideration, warning signs and signals

- Environmental controls – illumination, temperature, noise, vibration, chemicals

Operation phase

- Operation mode – operator, safety monitoring, teaching mode

- Nonoperational mode – dwell time, maintenance, programming

Safety should be emphasized from the beginning of the planning phase through every minute of robot operation. As many safety measures and hazard control techniques as possible should be implemented in order to eliminate/reduce/control robot-related worker injury exposure.

A suggested robot workplace layout is as follows:

.jpeg?sfvrsn=dbf923b1_1)

.jpeg?sfvrsn=c50521b1_1)